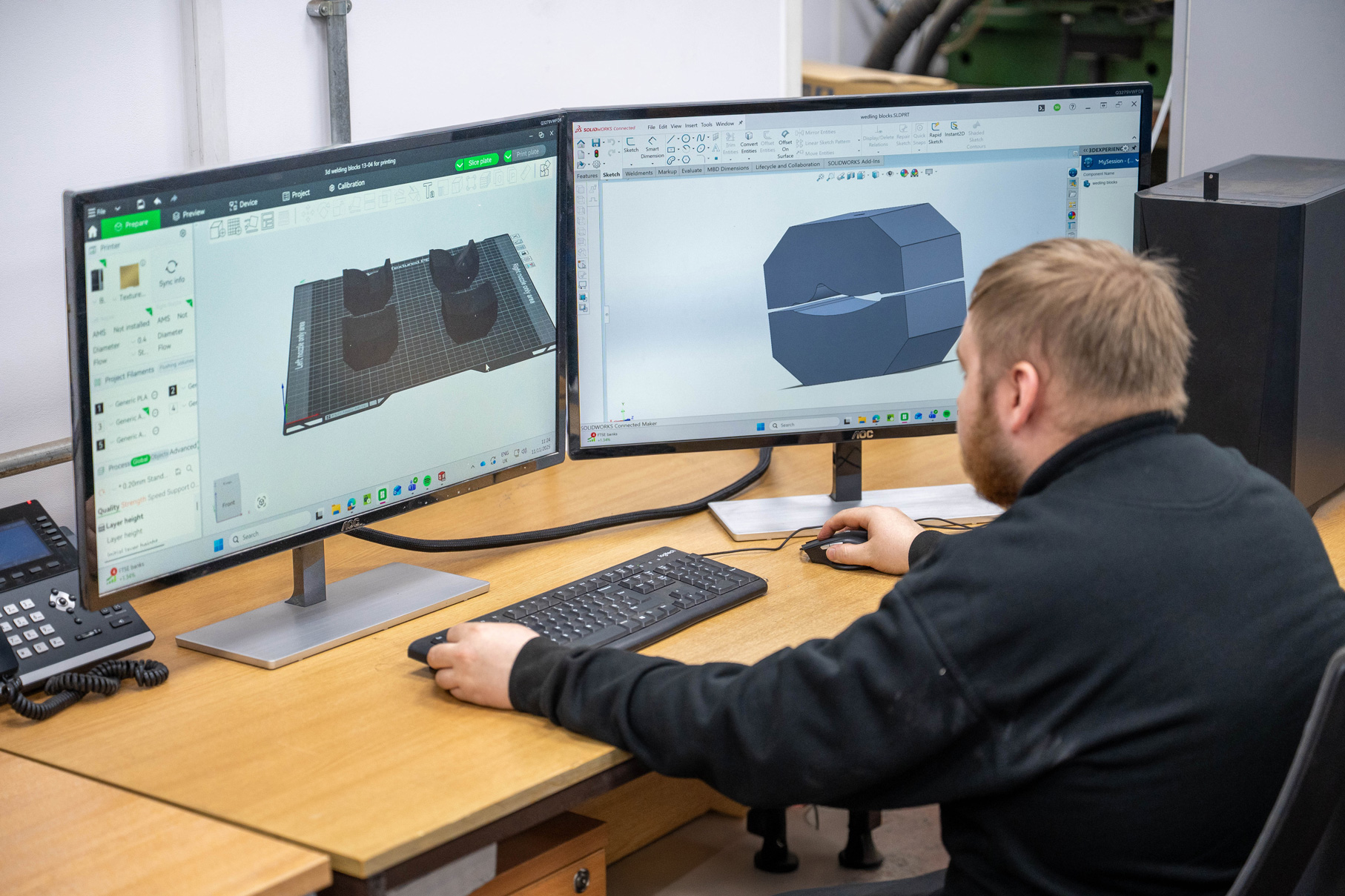

At Eagley Plastics, we support our customers from initial concept through to full production, handling every stage of the process with care and expertise. From the first enquiry, we work closely with you to understand your requirements, offering technical advice and suggesting any design improvements that could enhance performance or manufacturability.

We manage all aspects of tooling development and provide clear guidance at every step, ensuring a smooth transition into production. Whether you need a bespoke extrusion, a complex moulding or a full assembly, we are here to advise on the most appropriate and cost-effective solution, giving you confidence and support throughout the entire journey.

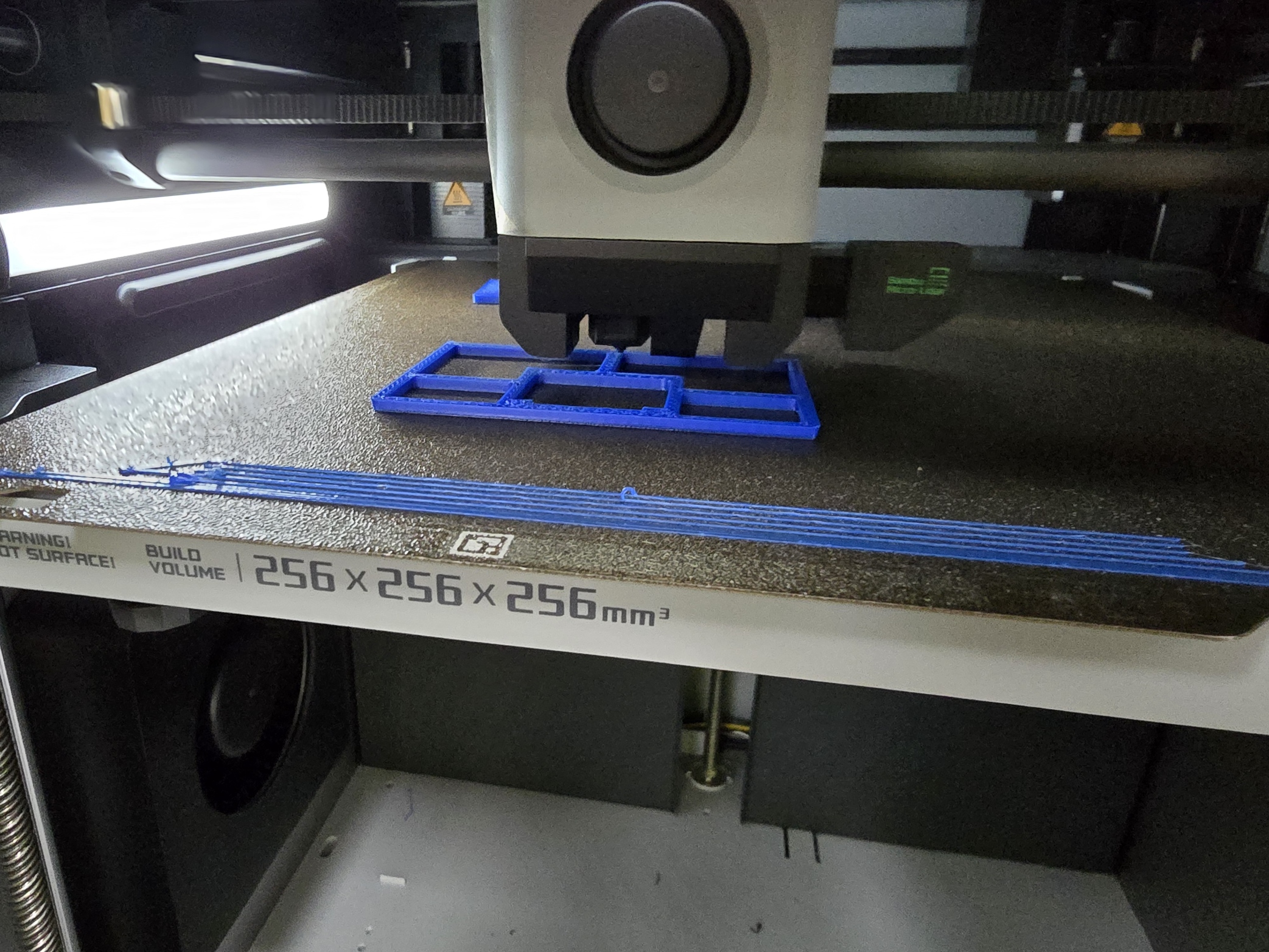

With flexible production capabilities, we can support everything from small development batches to high-volume manufacturing, adapting quickly as your needs evolve. From material selection to process optimisation, we focus on getting every detail right so your product performs exactly as intended.

Our team is committed to meeting deadlines without compromising on quality, ensuring you have a partner you can rely on for both routine orders and time-critical projects.

Above all, we pride ourselves on being approachable and responsive. Whether it’s solving a technical challenge, scaling up for a major project, or turning around urgent work, we bring the same dedication and expertise to every job – so you can move forward with confidence knowing we’ve got you covered.